For Singapore’s manufacturers, resilience is the name of the game

This is an exciting time for the manufacturing industry.

A host of new technologies, processes, materials, designs, production and other business capabilities are impacting the manufacturing sector, transforming it into a dynamic, future-ready industry.

As the leading manufacturing hub in the region, Singapore recognises the need for more innovative solutions to keep up. The government is firing on all cylinders to transform local enterprises, attract investments to set up cutting-edge manufacturing facilities, and develop talent to achieve its ambitious growth target for the sector - 50% over the next ten years.

A key focus that underlies this ambition is to leverage technologies under the widely-termed Industry 4.0 (I4.0) to revolutionise how local manufacturers have traditionally operated. The only way they can stay competitive is by embracing digital transformation to fuel innovation and productivity gains.

Beyond that, the current commercial climate also demands manufacturers to have a renewed focus on customer-centricity and agile supply chains.

In my role, I work directly with the industry to understand the emerging exposures faced by the manufacturing industry. Below are some of the most salient risks we see facing the sector, and each carries the possibility of major operational disruptions, bodily injury, property damage, financial loss, litigation and reputational damage.

-

Cybersecurity is having a moment

New technologies are changing how and what items are being manufactured. Processes that used to be manual are now digitised, networks have transitioned to the cloud, and the products themselves have more technology embedded.

The sheer myriad of I4.0 technologies may already be overwhelming for manufacturers, particularly the small and medium enterprises (SMEs). As focus tends to be on implementation, many often overlook critical areas such as the cyber vulnerabilities that come with widespread technology deployment. The more that products and processes are electronically linked, the more vulnerable they become to cyber-attacks, resulting in anything from unauthorised access to systems and data to complete operations shutdown.

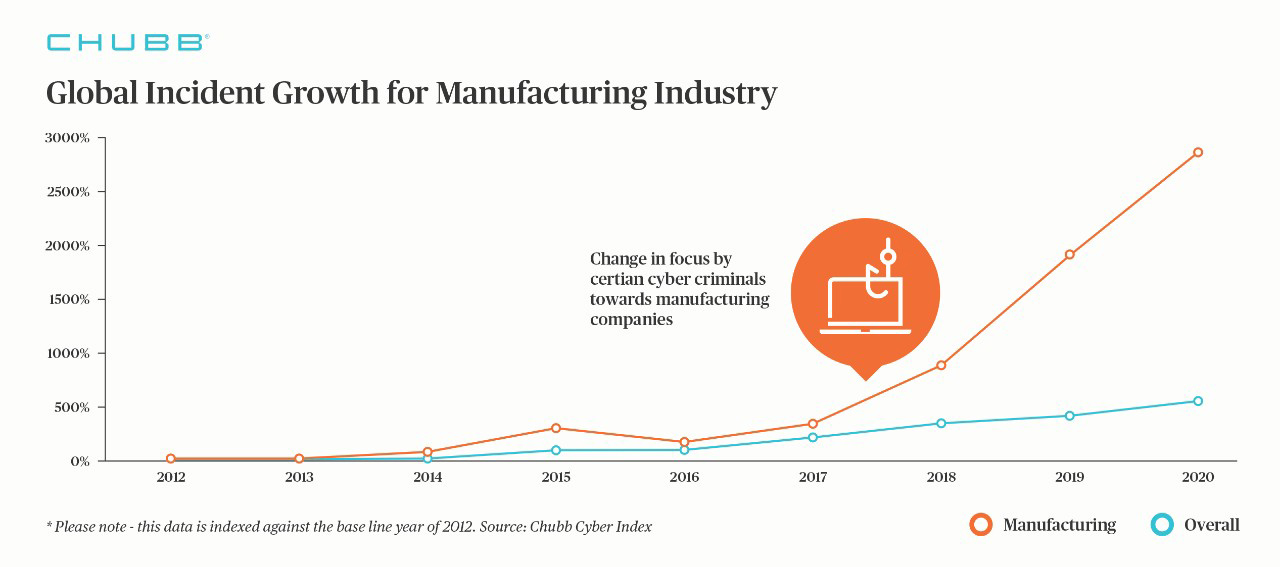

In fact, cyber-attacks targeting the manufacturing sector have increased both in numbers and severity. Chubb’s global data suggests that in 2020, manufacturing is the second most targeted industry for cybercriminals. In addition to the significant increase in cyber incidents, the average cost of a cyber claim is also at an all-time high.

-

Expanded service offerings are a gateway to increased exposures

In a bid to improve customer-centricity and revenue, many manufacturers are switching from a product-only model to one that includes more value-added services such as maintenance, installation, design, consulting and training.

Coupled with the fact that more smart products are being manufactured in a modern facility, both kinds of new offerings imply a more intimate relationship between a manufacturer and its customers, whether it is sharing data from smart products or installing and servicing products after they have been sold. With manufacturer and customer being connected in more ways and for a larger part of the product lifecycle, it adds an extra dimension to the risks that manufacturers could be liable for.

Manufacturers must be conscious that they need protection against compensation demands or lawsuits for a financial loss incurred by a customer, which could stem from a product or service defect or not meeting customer expectations, specifications or contractual requirements.

-

Integrated supply chains are not without their cons

Supply chain is a huge pressure point for manufacturers and the entire value chain as we have seen over the past two years. The pandemic and incidents such as the Suez Canal blockage have completely broadened our perspectives on the types of events that can hamper the supply chain.

But the threats don’t end there.

The increasing interdependent relationships between manufacturers, customers and suppliers have led to greater integration between all parties alongside third-party logistics, IT, and financial service providers. With the enablement of digital technologies, an enormous amount of sensitive data is stored and transacted between parties. Once the network is compromised, there could be cyber-attacks against any (or every) stakeholder in the supply chain.

In addition, with an increasingly integrated supply chain, manufacturers’ reliance on suppliers to provide component parts or sub-systems underscores the importance of sourcing and quality control. This is because a defect in a small component could trigger a domino effect on the factory floor.

For more in-depth discussions, read these articles to examine the diverse internal risks and external risks that manufacturers face.

Uncertainty comes in many shapes and forms. I recommend thinking about exposures in a new way as you confront challenges that may not have existed in the past. With a broader view of risks, you can anticipate challenges better, seize opportunities faster, and emerge from setbacks stronger.

Modern challenges require modern solutions

At Chubb, we have deep knowledge of the industry’s complex risks and are well-positioned to proactively help manufacturers of all sizes navigate and thrive in tomorrow’s world of uncertainty.

That’s why we introduced Chubb Assembly - a package policy tailored to help manufacturers become safer and stronger.

An industry first, Chubb Assembly provides integrated insurance coverage to address unique exposures – both traditional and emerging - facing manufacturers like yourself. It also offers scalable enhancements and modular solutions to help build your business’ resilience at scale, so you can free up resources to realise the full benefits of Industry 4.0.

Where to start

All of that said, don’t leave yourself open to missed opportunities. One of the many tangible building blocks for a resilient future is to involve risk specialists, identify and manage your exposures early.

A solution that includes:

- knowledgeable risk engineering services;

- broad cyber insurance;

- errors & omissions coverage that close the gaps inherently found in traditional insurance programmes; and

- protection against any bodily injury or property damage claims that stem from product failure;

can help address a risk event if one occurs and, more importantly, prevent one from happening in the first place.

Industry 4.0 and manufacturing risks

Industry 4.0 has revolutionised how local manufacturers do business.

As uncertainty comes in many shapes and forms, it's time to think about new exposures for which you may not be fully prepared.

No part of this article may be reproduced in any written, electronic, recording, or printed form without written permission of Chubb.

Disclaimer - The content of the above article is not intended to constitute professional advice. Although all content is believed to be accurate, Chubb Insurance Singapore Limited (Chubb) makes no warranty or guarantee about the accuracy, completeness, or adequacy of the content of this article. Users relying on any content do so at their own risk.

Have a question or need more information?

Leave your contact details and our representatives will get in touch with you.