Developers and manufacturers of medical devices and equipment pursue admirable goals: to reduce suffering and improve and extend human life. But they face numerous risks in pursuit of these goals, including the risk of destructive, costly, and life-threatening plastic fires.

Fortunately, plastic fire risk can be mitigated by taking preventive actions. As a first step, risk managers and safety personnel should identify how and where plastic fires can arise.

Why is manufacturing with plastic a fire risk?

There are many types of materials collectively known as plastic. Medical plastic products are primarily made of thermoplastic materials, which offer safety and performance advantages. Thermoplastics can be reheated and remolded, steam sterilized, and recycled, among other benefits.1

While thermoplastics are central to medical product manufacturing, they also represent a fire risk. Manufacturing plastic and manufacturing with plastic both pose fire risks. High heat is needed as part of the chemical process — polymerization — that creates plastic. For manufacturers creating end products with plastic raw materials — such as plastic resin pellets used in injection molding — heat is also needed.

While flame retardant chemicals can be incorporated into plastic products, most plastics are highly combustible — and plastic fires can spread quickly and produce smoke with dangerous chemicals.2 Harmful vapors can also be released when manufacturing with plastics, even when fire is not present.3

Sources of plastic fires in medical product manufacturing

When evaluating medical product manufacturing operations for plastic fire risk, consider focusing on the following four sources:

- Combustible plastic dust — Plastic dust produced in the manufacturing process can be highly combustible. Exposed to heat, plastic dust can evaporate and produce a volatile vapor. Proximity to flames or high heat can cause the vapor to catch fire — or explode — and ignite other materials.4

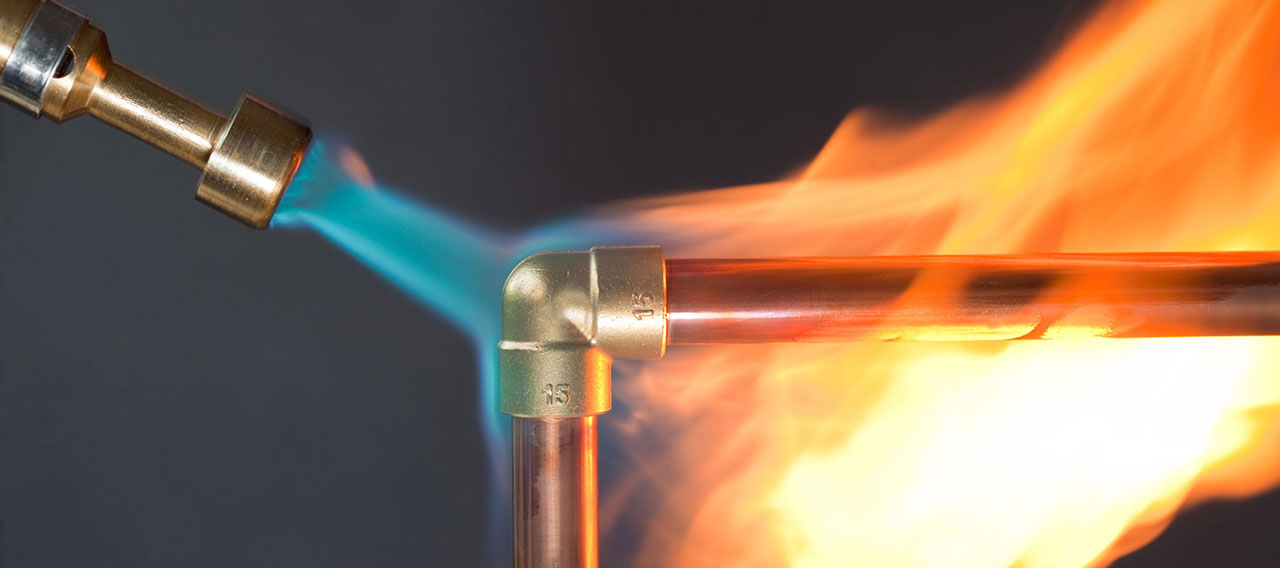

- Hot work — Any hot work in medical device manufacturing facilities, such as welding, cutting, soldering, and sterilization, poses a fire risk. When combined with the proximity of plastics and plastic dust, hot work can lead to fires.

- Combustible insulated panels — Different types of panels are used both in manufacturing facilities and on equipment, such as imaging machines where metal is not suitable. These panels may be combustible, and fires within panels may not be accessible to sprinkler systems.5 For medical equipment containing plastic housing, faulty or depleted batteries within can start fires.6

- Ignitable liquids — The process of molding and finishing plastic medical products may include the use of ignitable liquids, including solvents, coatings, lubricants, and fuel. These liquids can be ignited by heat, faulty machinery, static electricity and electrical shorts, lighting, and other sources.7 Ignitable liquids such as alcohol are also frequently used for cleaning in medical product manufacturing.

Mitigating plastics fire risk

Once you’ve identified key sources of plastics fire risk, create, or update a comprehensive fire risk mitigation program. Here are four key steps to help reduce the risk of plastics fire:

- Ensure sprinkler systems are adequate and properly maintained — An adequately designed and installed, well-maintained sprinkler systems is critical for mitigating the impact of a plastics fire in a manufacturing facility or warehouse. Sprinkler systems will be the most effective when designed and installed to meet the current benchmark National Fire Protection Association (NFPA) 13 standard.8 It’s important that the sprinkler system be designed to meet the increased fire risk of manufacturing with plastic — and using plastic in packaging and storage.9

- Conduct infrared inspections — Potential — and unseen — fire hazards may be identified and remediated by conducting an infrared inspection of facility electrical panels. This inspection can reveal defective or faulty wiring, hot spots, overloaded circuits, poor insulation, and water leaks — all of which can lead to fires. Infrared systems can also be used to inspect mechanical and steam systems. These inspections can help prevent both fires and operational disruptions.10

- Focus on training and operations management — A well-trained workforce that follows clear rules for fire safety can help prevent fires. It is especially important that employees whose duties include hot work and handling combustible materials receive training and written fire safety policies.

- Connect with your local fire department — Conduct periodic walk-throughs of your facilities with local fire departments so they can familiarize themselves with your operations and layout of buildings. Fire department personnel may also be able to identify undetected fire hazards.

Strong fire mitigation programs will help medical device manufacturers ensure their operations are not interrupted due to a plastic fire and resulting smoke and water damage.

1https://bmpmedical.com/what-plastics-are-used-in-medical-devices/

3https://www.epa.gov/chief; https://www.sentryair.com/plastic-fumes.htm

4https://www.sonicaire.com/combustible-dust-in-the-plastics-industry/; https://www.sonicaire.com/combustible-dust-and-the-plastics-industry/; https://www.plasticsnews.com/perspective/nfpa-652-beyond-dust-hazard-analysis

5https://risklogic.com/the-dangers-of-plastic-composite-panels/

6https://medicaldevicehq.com/articles/how-to-identify-and-manage-critical-components/

7https://www.imua.org/Files/reports/AnUnderwritingGuidetoPlasticManufacturing.html

8https://www.nfpa.org/codes-and-standards/all-codes-and-standards/list-of-codes-and-standards

10https://www.tfp1.com/blog/how-infrared-electrical-inspection-reduces-risk-of-building-fires

Insights and expertise

This document is advisory in nature and is offered as a resource to be used together with your professional insurance advisors in maintaining a loss prevention program. It is an overview only, and is not intended as a substitute for consultation with your insurance broker, or for legal, engineering or other professional advice.

Chubb is the marketing name used to refer to subsidiaries of Chubb Limited providing insurance and related services. For a list of these subsidiaries, please visit our website at www.chubb.com. Insurance provided by ACE American Insurance Company and its U.S. based Chubb underwriting company affiliates. All products may not be available in all states. This communication contains product summaries only. Coverage is subject to the language of the policies as actually issued. Surplus lines insurance sold only through licensed surplus lines producers. Chubb, 202 Hall's Mill Road, Whitehouse Station, NJ 08889-1600.